Petrotech Company is carrying out major repairs of your engine with the help of its specialists.

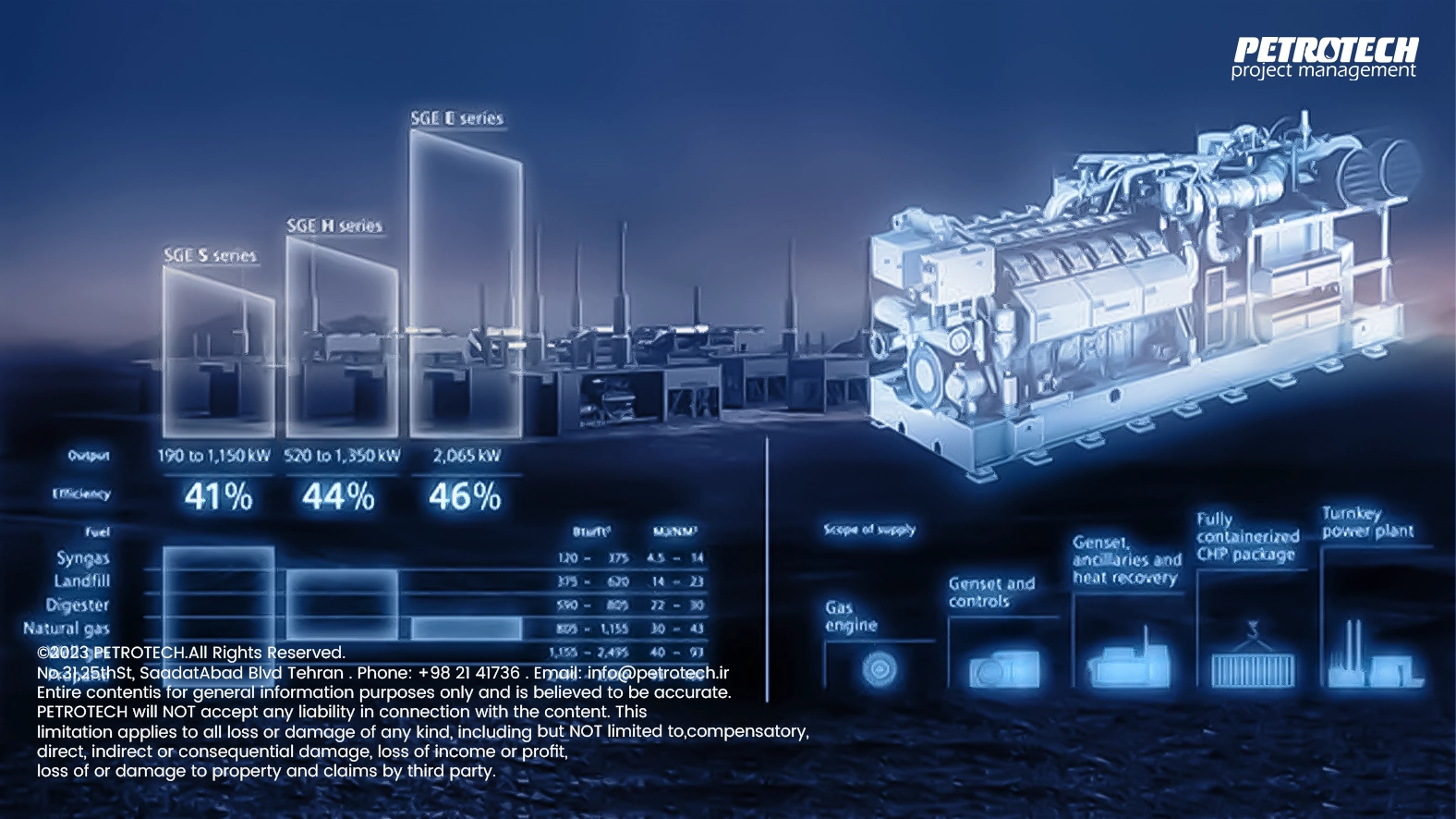

In order to ensure a generator has the highest levels of availability, scheduled maintenance should be completed at specific points in the operational life of the gas engine. The operational life is measured in number of actual operational hours (hours run). Each engine has a specific maintenance schedule that is be related to the quality of engine’s fuel gas. For example, natural gas is cleaner and less challenging than landfill or biogas. Attendance for replacement of consumables such as oil and filters typically occur every 1,000 – 2,000 operational hours. Scheduled intermediate services occur at 10,000-hour intervals.

Finally, the gas engine has a full overhaul at 60,000 hours of operation. At the 60,000-hour overhaul ideally the engine will be taken away from the site to be stripped down and fully serviced with specialised machinery. If we are provided enough notice, a reconditioned swing engine can be brought in at the corresponding time for the engine overhaul. This provides the lowest down-time for your generation plant. Alternatively, where it is not possible to remove the engine, it can be overhauled in situ. This is not an ideal situation and will take longer than using a swing-engine.

The gas engine product is renowned for its reliability, however from time to time there will be a need for unscheduled maintenance. This could be due to trips, problems with the fuel gas quality or problems with components. The best solution to counter any unscheduled maintenance is to ensure your gas meets the technical instruction for fuel gas quality and support this with a full maintenance agreement with Petrotech. It is also possible to set up remote monitoring of your gas generation facility. Remote monitoring enables you to monitor performance of your generator and to be notified via text message or e-mail about trips or unplanned shutdowns.

When your engine is overhauled it may be possible to upgrade all components to the latest versions. This may provide additional benefits to the customer from increased generating efficiency.

Petrotech provides you with the opportunity to ensure the safety of your drilling rig for deployment at sea and operations by conducting periodic and timely monitoring and inspections. Our services cover all operations from design and construction to operation and repair.

Perform all services related to inspection of unloading, loading and inspection equipment during the construction of oil and gas rigs and platform equipment and inspection services before and during transportation for oil rigs installation, cabling and offshore piping projects. Provides craftsmen in the field of marine services and shipbuilding.

Petrotech helps Oil & Gas Field Services deliver fast and superior service for complex service-oriented jobs in rugged, outdoor environments such as well sites, refineries or spill sites.

In a world as dynamic as Oil & Gas, the requirement for awareness and responsiveness of all things within the operation is essential. To streamline operations, reduce costs and improve profitability, organizations must be able to handle complex, diverse and changing mobile oil and gas field service management needs.

Petrotech provides operational readiness from the early stages of a project, accomplishing smooth transition from EPC to stable commercial operation through development of organizations, management systems and supply chains.

Through non-destructive inspections and other methods, Petrotech inspects and identifies available facilities and collects data for optimal maintenance programs with the customer. Based on the knowledge gathered in maintenance jobs, we develop the services provided to our customers by providing an advanced facility detection system with predictive maintenance functions.

Petrotech provides manpower, experienced supervision and direct management to increase the performance of your assets, improve productivity and reduce your costs.

Due to our extensive experience in the oil, gas and petrochemical industry over decades, we can range from repair, maintenance and operation (O&M) activities at all stages of the asset life cycle, from engineering to procurement to business operations. And support late operations.

We implement a range of smart processes and procedures. This includes preparing manuals, procedures, work plans, and monitoring related systems (such as operating management systems, computer maintenance management systems, and safety management systems, among others).

Our scalable maintenance method is designed to optimize maintenance operations and activities. We determine which of your people are equipped with the most efficient method to complete the work required and adjust their workload accordingly. Of course, we can provide training to fill any skills gaps in your workforce and ensure business competency.

Petrotech is the authorised supplier of genuine gas engine spare parts in Iran.

we have the largest inventory of gas engine spare parts in the country. Spare parts availability is critical if engine downtime is to be kept to a minimum. Petrotech recognizes this fact and we hold the highest levels of stock of genuine spare parts. These spare parts can be dispatched at short notice where required in the country.

Our spare parts team has a reputation for friendly and excellent service and is familiar with spare parts. This ensures that any problems with parts identification or supersessions are dealt with quickly and efficiently, thus ensuring that the correct item is supplied to the customer first time, every time. All spare parts are carefully stored on self-contained racking units in our quality controlled, purpose-built warehouse, operating to ISO9001 standards.

Our warehouse stocks are managed by the latest in computer software which replenishes parts when a minimum stock level is reached, ensuring a rapid turnaround on all purchase orders.

In addition to new genuine parts, Petrotech can also offer a wide range of re-conditioned and service exchange items. Our stocks include motors and alternators (swing-engines for major overhauls), all series cylinder heads, connecting rods, water pumps, turbochargers, intercoolers, starter motors and oil pumps.

In Petrotech also has a facility dedicated to the reconditioning of used cylinder heads. This facility reprocesses used cylinder heads, giving them a new lease of life and providing a quality control service to our customers.

We have long-term experience in engineering and project management. Petrotech has engineers and technicians who contribute in projects and in operating organizations in long or short-term assignments.

Petrotech is a specialist engineering company in the field of structural calculation and drawing for the onshore and offshore industry. We have very high competence in advanced analysis, 3D modelling and production drawings and deliver projects from study stage to complete installation.

Our core services are within Installation, Rig Drill Support, IMR (Inspection Maintenance & Repair), Decommissioning, Utilities and Communication. We deliver engineering, project management & operational modifications.

As a leading and innovative provider of subsea engineering, Petrotech is proud to send senior pipeline engineers to the field to carry out important operations. Our expertise in the pipeline field includes advanced analysis and geotechnical support.

Petrotech provides a range of services including integrated maintenance and construction project delivery, commercial diving services, survey, geophysical and geotechnical services, and ROV services. Our extensive scope of services ranges from subsea stabilization, specialized subsea engineering solutions, and manufacturing to testing and assembly, and dry underwater welding.

Our supply chain group has teams selected in all major areas of our business as well as in other major locations to support our business. And we have a specialist buyer, accelerator, logistics officer and material controller. Due to our high annual costs, we have first-class expertise in managing high value orders.

With our international locations and the experience of our supply chain professionals, we can provide excellent sourcing, expediting and logistics support to our projects. Where necessary, we also have strong relationships with third party agencies who we can engage to enhance our service on a case by case basis.

Thanks to our flexible commercial delivery models, we can procure directly in support of your projects, returning value through a gain share approach.

Local delivery has always been central to the way Petrotech work, underpinned by robust business practices, and we evaluate our impact by calculating in-country value (ICV). We work with local suppliers and develop local capabilities wherever possible, and all goods and services are procured in an ethical and cost-effective manner.

We provide life-of-asset engineering capabilities for brownfield and greenfield projects; from consultancy services through concept and FEED into detailed design, procurement and commissioning. This capability extends into late life and decommissioning.

We strive to deliver value-adding engineering solutions so you can unlock increased value from your oil and gas assets.

We are proud to support projects of any size and scale, onshore, offshore, subsea or subsurface; from small brownfield modification projects to large subsea tiebacks, and from major facility upgrades through to greenfield mega projects.

We leverage Petrotech’s Group capability in delivering lump-sum turnkey EPC and its operating and maintenance expertise to enhance our early engineering solutions, allowing us to recommend best-fit, constructible and operable solutions that are benchmarked against real time procurement data and schedules. Our extensive procurement benchmark database means that we can identify the most accurate prices currently available.

Our market offerings range from small reimbursable man-hour projects to major brownfield modification projects (including fast track) as well as call-off contracts, engineering services framework agreements and other performance-based strategies.

And, depending on your objectives, we can fast track our projects by seamlessly integrating early engineering and execution activities to improve schedule – in some cases by up to 12 months – and accelerate revenue recognition.

No matter the size of the project, we pride ourselves on challenging conventional thinking at the outset, bringing in our operations and construction expertise at the earliest stage to ensure our solutions are safe, technically sound, fit-for-purpose and cost effective.

We have executed projects for onshore and offshore oil and gas production facilities, as well as downstream processing, in some of the most environmentally and logistically challenging locations.

Project management services are at the heart of our successful and sustainable project delivery capabilities.

The projects we deliver are typically large and complex, requiring strong management and control to reach a successful conclusion.

We use internationally recognized project management frameworks and processes as part of our quality management system for the management and control of all our projects, whether these are engineering, procurement, construction or commissioning projects.

Project management teams are usually involved from start to finish of a project, and are critical to its success. Our people have proven delivery capabilities, from concept stage through to execution, delivery and start up.

Scale and complexity is never a problem for us. We have the manpower to cover projects of any size, and we tailor our teams based on the individual requirements of the client and project.

Our technical services underpin and augment our asset management capabilities, and are available on a standalone basis as needed.

Decades of experience in maintaining and managing assets and expanding Petrotech’s capabilities have enabled us to reduce operating costs and improve productivity across onshore and offshore facilities.

Petrotech’s Technical Services Division provides our customers with best-in-class diagnostics, testing and O&M management to ensure their energy facilities generate at the highest levels possible.

Our experienced team of engineers, technicians and technical experts provide independent engineering reports, start-up services and more, all focused on improving and optimizing system performance to maximize the return and longevity of your assets.

We position your assets for success by planning and assuring operational readiness

We ensure the necessary systems, processes and selection criteria are met for asset purchase and management

We ensure that transition is accomplished with no impact on safety or operations

We measure and track oil and gas products from origin to point of sale

We audit vessels servicing the offshore industry to ensure safe operations

We provide specialist repair, maintenance and manufacture solutions for mechanical equipment

We’re combining mobile technologies and our proprietary software, to digitalise all forms of maintenance and inspection:

By digitalizing the way, we plan, execute and report, our Connected Workers are achieving up to 200% improvement in efficiency compared to traditional approaches.

Using data driven technologies to streamline our processes

Digitising the way we plan, execute and report is delivering smarter, faster results for less:

Planning – We use our software to scope and group work to digitalise our work packs.

Execution – Our RealWear headsets and digitalised work packs with voice-controlled computers allow inspection personnel to capture data, share information and access your CMMS and advice from SMEs – all in real-time. This reduces time, improves accuracy, and lowers costs.

Reporting – Our proprietary software, automates the reporting process, providing instant access to visual, customisable data driven dashboards. Metrics and Key Performance Indicators can be quickly and easily analysed.

This approach can be applied across a wide range of workflows, including inspections, maintenance, operations, quality and HSE, which we tailor to suit our clients’ needs.

Solutions include operations readiness, maintenance, inspection, and inventory optimisation through to late life asset management and decommissioning strategies.

Our fit-for-purpose business processes are designed to drive operational excellence that can integrate seamlessly with your existing systems.

Combining our operations capability with our wider, life of asset services enables us to provide integrated solutions incorporating engineering, well engineering and training capabilities

As a Service Operator, we provide competent people to staff your asset. These people are supported by our Competent Person Profiles to ensure the right people are in the right roles and have the necessary support for their personal development. A robust communications function ensures all core information is understood by all personnel and that campaigns around targets reach and are adopted by all employees.

We provide a range of comprehensive project management and engineering services across the entire asset life cycle.

We combine specialist pipeline engineering studies with subsea capabilities and the development of large multi-discipline oil and gas development projects to develop specialist pipeline management solutions.

This service is supported by our due diligence and transition capabilities.

We combine creative thinking with practical experience and data from projects and operations to help unlock value from energy assets.

Our engineering and consultancy services span the energy asset life cycle, from concept design, screening and selection, through engineering into project execution, pre-operations and operations support through late life and into decommissioning.

Our experienced, multi-disciplined, teams have a rich skill set enabling us to solve the most complex project challenges. We support across the energy landscape, from oil and gas (upstream and downstream), to services in support of wider decarburization objectives, offshore wind, and other clean energy sectors.

We are flexible in our delivery, providing these services through framework agreements, as discrete projects or as part of large-scale integrated projects.

Focused on supporting at the earliest project stages, we provide services to support field development planning, concept design, screening, and selection to help smooth the patch to project sanction. We use our EPC experience and operations know-how to shape our solutions, so that your project can progress with robust designs, costs, and schedule estimations that can be trusted. Our consultancy services include:

Our project execution services span into engineering execution, detailed design as well as procurement, commissioning, and site support. We can provide skilled, experienced project management teams to support your projects. Our engineering team is multi-disciplined and has experience in delivery both early engineering and detailed design. This capability is complemented by a strong technical consultancy team, enabling us to advance even the most complex projects.

Our understanding of the issues that affect asset performance and access to true operating data allows us to create solutions that:

Improve safety and integrity

Increase reliability and availability

Reduce cost

Assure compliance

Improve the management of risk

We not only identify opportunities for improvement, but implement those measures too, through our integrated services. Our services support the operational life cycle, from pre-operations through to late life.

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.