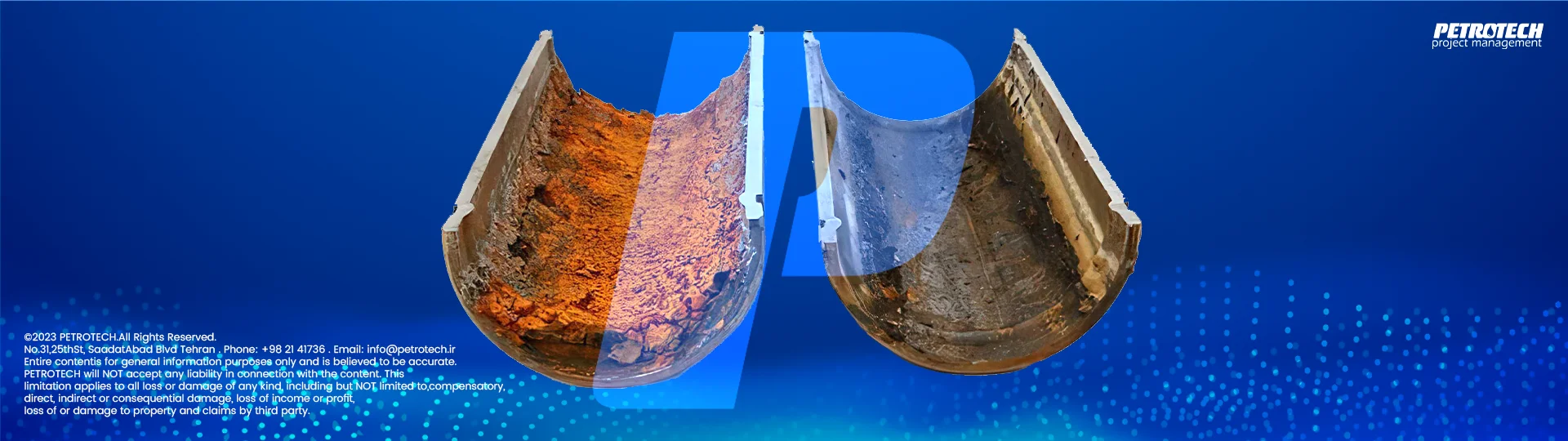

Corrosion is the most common time-dependent threat for pipelines. Pipeline operators worldwide spend billions of dollars mitigating the effects of corrosion. Managing this threat is critical in ensuring the future integrity of a pipeline. For effective corrosion management, the cause of the corrosion must be known, and reliable estimates of the corrosion growth rate are a critical input.

PETROTECH’s Corrosion Growth Assessment (CGA) identifies the cause and quantifies the rate of corrosion activity in a pipeline. Our expert corrosion engineers analyze the corrosion processes using state-of-the-art methodologies, such as flow assurance, and evaluate the credibility of corrosion rates calculated from inspection data. CGA therefore provides a detailed view of how corrosion has developed over time and significantly increases operators’ confidence in the future integrity of their pipeline.

Our advanced corrosion growth service CGApro provides a holistic diagnosis of corrosion based on design and operational data, flow assurance models, corrosion modelling software, cathodic-protection analysis, coating evaluation, in-line inspection results, and comparisons between inspections. After the identification of the causes of corrosion, our experts support operators with recommendations for mitigation, control, and monitoring.

Tracking corrosion activity with regular repeated CGAs enables operators to monitor the effectiveness of their corrosion mitigation activities.

CGApro is supported by our Automated Signal Correlation and Normalization process, AutoSCAN. AutoSCAN precisely matches metal loss indications between two axial field magnetic flux leakage (MFL-A) inspections, using pattern recognition technology. Historic depth changes are then estimated using the change in signal amplitude and shape. The AutoSCAN output offers unrivalled support to operators, not only highlighting the peak activity within a pipeline, but also providing a full and accurate corrosion growth rate distribution which can be used to estimate the pipeline’s remaining life and support life extension initiatives. Corrosion activity associated with shallow features can be identified, which allows for the early identification of corrosion activity before significant damage is caused.

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.