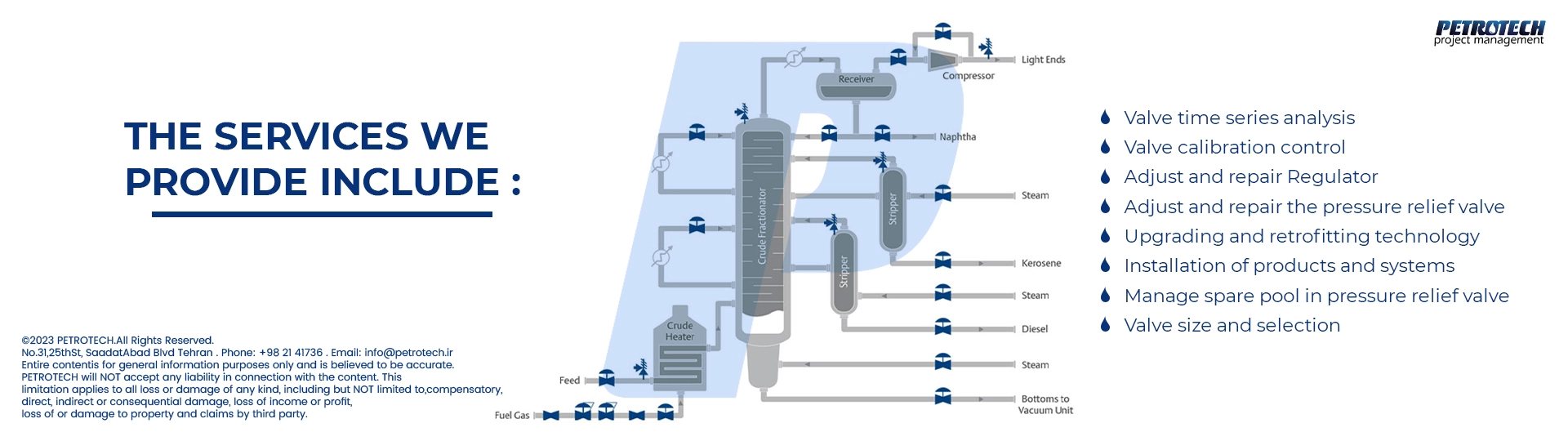

Petrotech uses advanced control solutions for raw distillation units, along with the best measurement features that save energy costs.

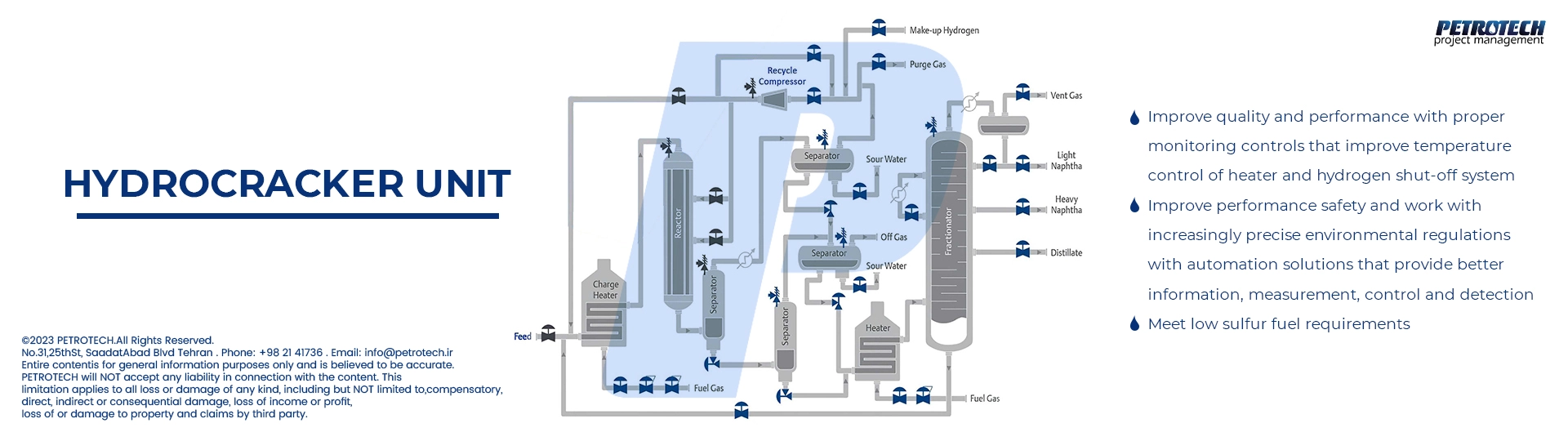

This unit is very important for supplying low sulfur diesel while taking advantage of the opportunistic market conditions between gasoline and diesel. Therefore, safe and effective operation of this unit is essential. Safety is also a challenge due to the high pressures of hydrogen, hydrogen sulfide and possible swelling of the reactor in this unit.

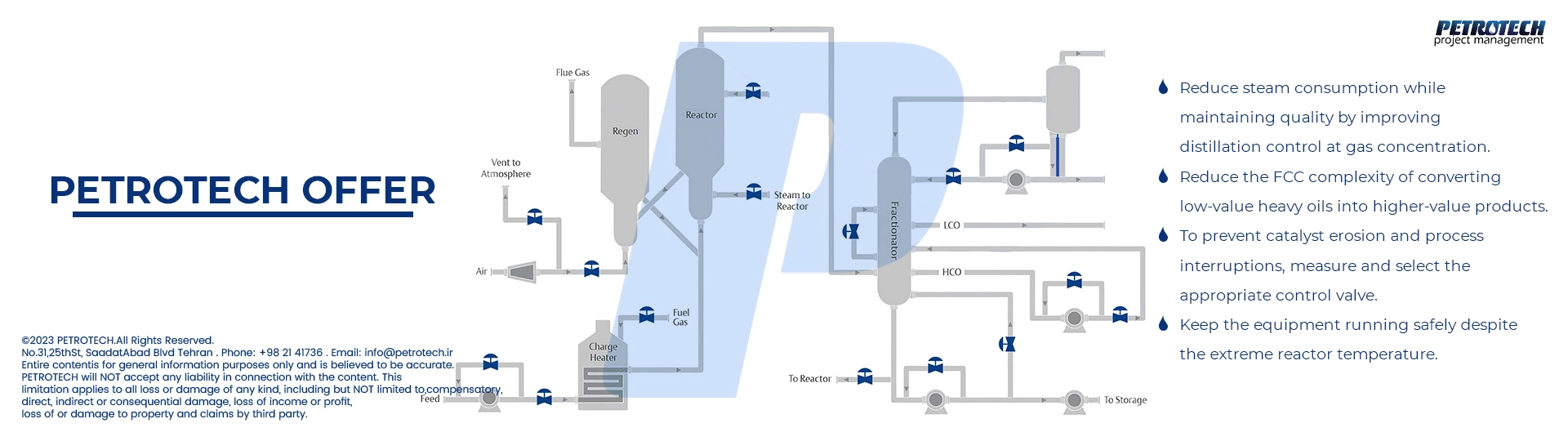

Fluid Catalytic Cracking, or FCC, is a dynamic and complex process that operates in harsh conditions where it is always dangerous to connect to the power supply and return the catalyst. By processing a significant portion of the refinery heavy oil in the FCC unit, deceleration or shutdown can directly affect the refinery’s profitability. The FCC unit is also an important source of butane and pentane olefins used in refining processes such as the alkylation unit. As a critical unit in the refinery, the optimal operation of the alkylation unit is essential.

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.