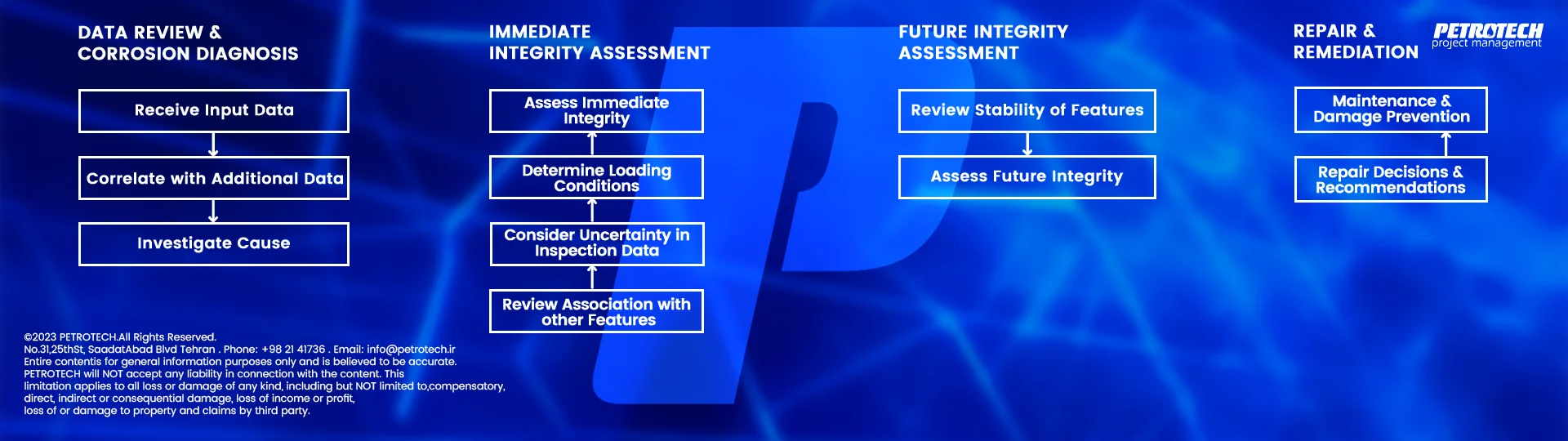

Inspection is an essential component of the Integrity Management Process, but understanding the implications of inspection results and how they should inform repair and mitigation planning is key for effective Integrity Management. PETROTECH’s fitness-for-service (as defined in API 579 2016) assessment services will take your inspection results and tell you whether the immediate integrity of your pipeline is under threat, and when unacceptable defects could appear in the future, allowing for informed and safe repair planning. The cause of defects will be investigated and appropriate mitigation recommended to control future degradation. As partners in managing clients’ pipelines, we make a full contribution to achieving the best results for safe, profitable and responsible operation.

Pipelines are protected against deterioration in a variety of ways. For example, protective coating and cathodic protection systems are designed to mitigate against corrosion. But the effectiveness of these protective systems can diminish over time, and defects can develop in structures, adversely affecting the reliability, safety and performance of assets.

So when defects are identified during an inspection, key questions need to be answered. Is the integrity of an asset under immediate threat? Might a detected defect become larger, and, if so, can I predict its rate of growth to understand when it may become a threat to my asset in the future? And how did this defect initiate, and can I expect more defects of a similar nature? And, of course, is there anything that can be done to stop more of these defects from appearing?

As assets in oil and gas and associated industries worldwide continue to age, these questions are becoming more and more relevant. The sound examination and inspection of them – and assessment of their integrity – is critical in ensuring continued safe and reliable operation.

Our FFS assessment offers a comprehensive analysis of a pipeline’s current and future integrity. It sets out for our clients a clear program of repair, inspection and mitigation actions, which, when scheduled and completed, ensure safety and reliability.

A fitness-for-service assessment is often used by operators to demonstrate to regulatory bodies that the condition of an asset is clearly understood and that future actions are properly planned. Assessments can be conducted for a range of different defects.

Often completed following a multiple-technology in-line inspection (ILI), this assessment is completed by the industry’s largest and most experienced team of internationally recognized pipeline integrity experts working closely with highly experienced ILI data evaluators to ensure that any uncertainties associated with the inspection data are minimized and that the capabilities and limitations of the inspection technology are fully accounted for.

This close collaboration and joint understanding of integrity issues and the inspection system ensure that any questions related to the ILI data are clarified at an early stage and maximum value is extracted quickly and efficiently as an integrated part of an overall inspection and assessment project.

The majority of the FFS assessments we complete are for metal loss defects in pipelines. Assessments will determine the impact of all reported metal loss on the immediate and future integrity of the pipeline. Assessments are frequently combined with our CGApro service to ensure a cost-effective but safe repair plan for corrosion defects. The assessment can be completed using a variety of methods (API 579, DNVGL-RP-F101, ASME B31G among them) and can account for local regulations (for example US DOT). The underlying causes of any defects will be analyzed with input from our own experts in corrosion, materials, welding and integrity, and a clear set of mitigation actions will be provided to stop or deter defect growth and initiation. A repair plan and a recommendation for ILI re-inspections will also be provided.

By combining a number of assessment codes, PETROTECH has developed an initial screening assessment for dents, which accounts for depth, weld and defect interaction. Top-of-line (TOL) dents will also be identified and cross-referenced with previous data sets to ensure they are not a product of recent third-party damage. If dents fail an initial screening check, then a detailed surface strain assessment can be completed to check for potential cracking. Close collaboration with ILI data evaluators and a thorough understanding of ILI tool behavior ensure that any spurious data points and false strain indications can be removed.

The remaining fatigue life of the dents will be determined through the EPRG screening method, and, if needed, our FE-DAT program, which has been developed and proven in collaboration with Stress Engineering Services, can be utilized to generate stress concentration factors (SCF) for a less conservative assessment using S-N curves. Critical dents will be identified and their contribution to remaining life calculated, allowing for the generation of a repair plan.

It is a widely accepted good practice to evaluate unsupported sections of pipe or “freespans” to confirm that they will not be adversely affected by vortex-induced vibration and that they will not generate unacceptable bending stresses due to excessive length.

PETROTECH offers three levels of freespan assessment, all in accordance with the state-of-the-art industry guidance given in DNVGL RP-F105, starting with a simple screening assessment to a more thorough FEA-based. The level I screening assessment includes a check for local buckling and a basic fatigue assessment considering both in-line and cross flow natural frequencies. Maximum allowable freespan lengths will be developed, allowing for clients to gauge the need for freespan assessments following future ROV surveys.

A level II detailed assessment can be conducted for spans which fail the level I assessment, with software applied to an enhanced level of data to determine the acceptability of spans. A level III assessment consisting of an FEA model to consider further details – like the effect of pipe-soil interaction – will be conducted if spans fail the level II assessment. The FFS will determine the criticality of the freespans, and an ROV interval survey will be provided for those spans subject to level II and III assessments.

This assessment identifies the limit strain values for tensile fracture and compressive local buckling. Strains calculated based on measured pipe curvature are compared to the limit values for acceptability. The assessment can take account of any pipe body anomalies that have been identified on the pipeline within an area of high bending strain (for example near areas of metal loss and girth weld anomalies). A more detailed assessment can be conducted with an FEA model for individual sites to consider the impact of pipe/soil interaction and to predict the strain introduced by future movement. Specialist pipeline geotechnical experts guide our clients through the bending strain assessment process.

The results of ILI and in-field investigations will be consolidated and features assessed to determine their impact on the immediate and future health of the pipeline. A range of assessment methods will be considered (BS 7910, API 579, NG-18) and the most appropriate chosen – with client consultation. The future integrity assessment will consider fatigue and environmental (i.e. SCC) growth mechanisms where applicable. A summary of any associated activities – such as root cause analyses and metallurgical testing – will be included with the results of the assessment to provide a comprehensive list of mitigation and repair actions. We also provide comprehensive crack assessments within our Pipeline Integrity Framework for Cracking.

Our fitness-for-service deliverable provides a comprehensive overview of a pipeline’s condition in a clear and concise report. The report will support an operator in meeting code and regulatory requirements. It will also confirm the pipeline as reliable and, perhaps most importantly, safe until its next inspection. Reports may also include indications of remaining life of an asset, satisfying a client’s commercial needs and the regulations of a governing body while also paying proper respect to safety and operational requirements.

PETROTECH’s extensive track record in completing FFS assessments means you will receive a service that has been developed and refined over many years. Experts in defect assessment and supported by top international professionals in fracture mechanics, fatigue, corrosion, stress corrosion cracking, welding and materials, PETROTECH’s team will ensure that any remedial actions are cost-effective and fit properly into the operation of your asset over the long term.

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.