Our EMAT inspection method is effectively creating and using ultrasound for the detection of cracks/stress corrosion cracking without the need for a liquid couplant. A secondary benefit of the EMAT technology is that it may detect disbanded coating.

This technology based on the generation of ultrasonic waves is expanding ultrasonic inspection methods from only liquid lines to gas pipelines. It has distinct advantages that make it the technique of choice for many applications with accurate 360-degree inspection and 100% line coverage.

Petrotech ultrasonic metal loss inspection tools work based on the direct measurement principle to ensure quantitative wall thickness measurements, superior detection, and sizing of metal loss anomalies, laminations, and inclusions.

In-Line Inspection allows Petrotech operators to have better information on the condition of their pipeline systems and develop adequate maintenance and repair programs. Adopting a proactive approach to addressing integrity threats enables pipeline operators to avoid production and consequential losses caused by Petrotech failures.

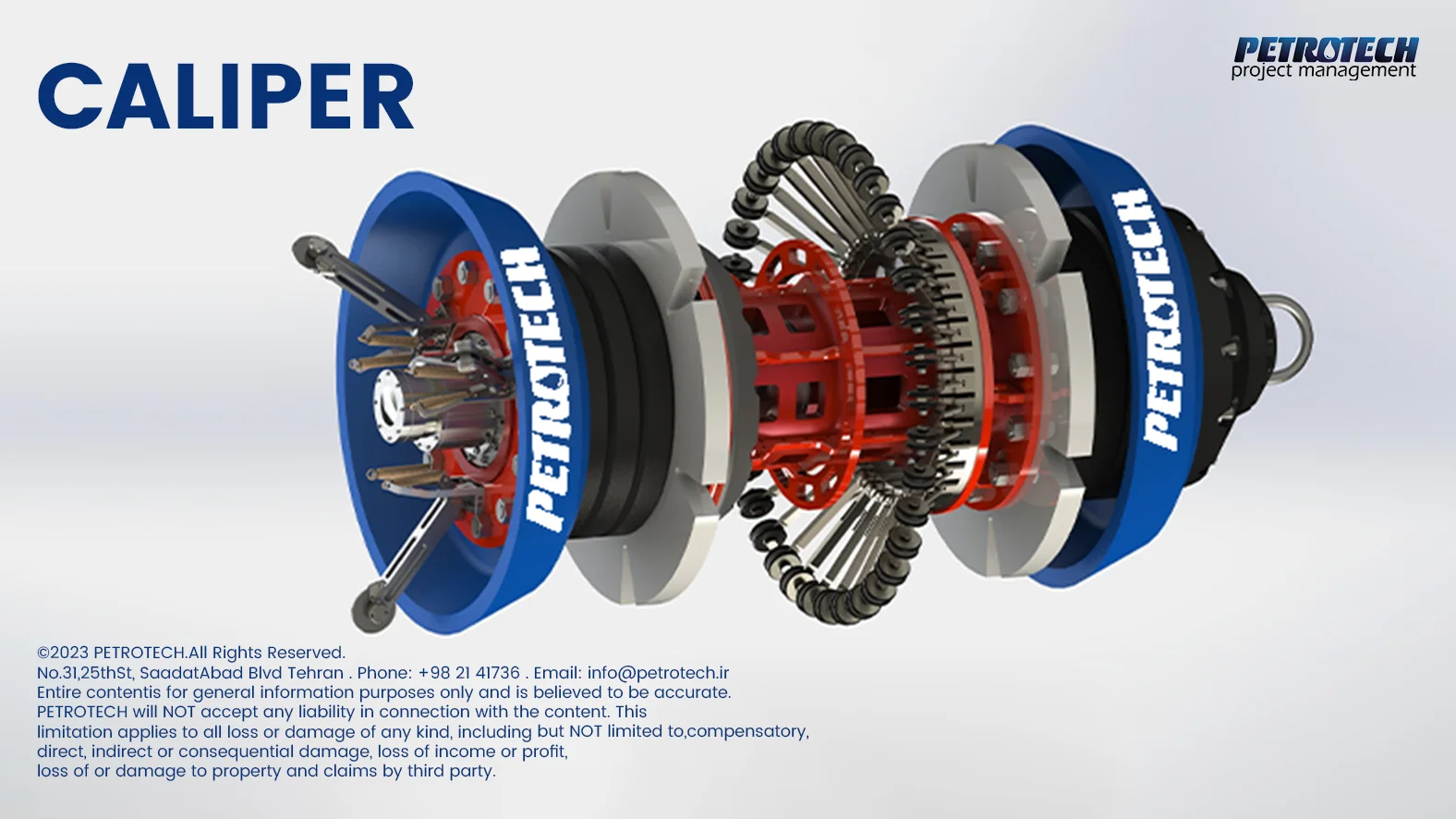

It is an industry common knowledge that the primary threat to Petrotech integrity is corrosion growth and growth of cracking anomalies. However, mechanical deformations can cause accelerated growth of cracking. Geometry features combined with corrosion can be a severe threat to pipeline integrity. These threats are difficult to assess with existing models or practices.

Significant reductions of Petrotech circular shape can negatively affect the flow of product and cause excessive consumption of power required for product transportation. It is vitally important to locate such geometry deviations on any Petrotech.

We provide geometry inspection services using caliper technology on all Petrotech sizes of the oil and gas industry supported by a large fleet of Caliper Geometry inspection tools.

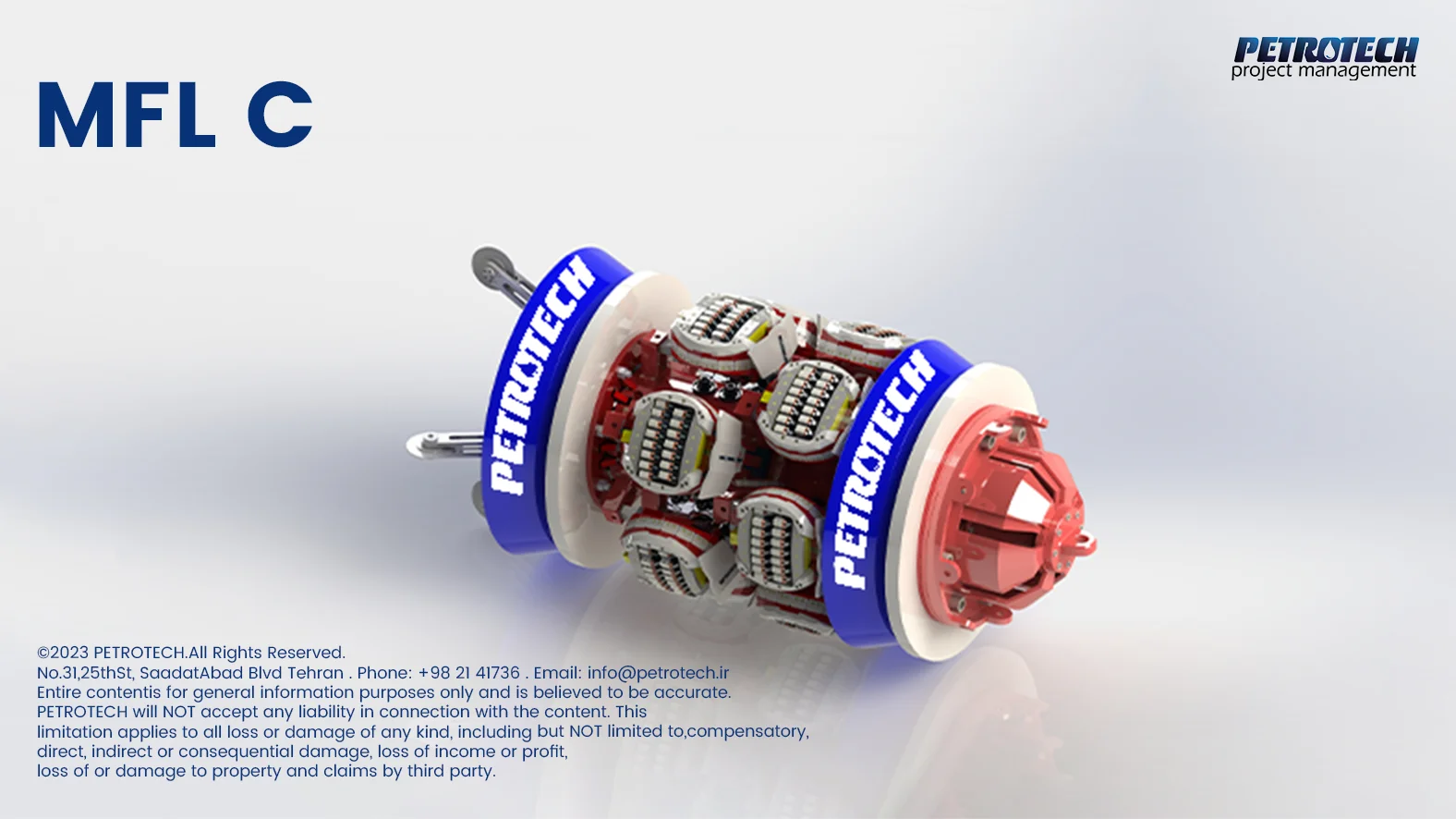

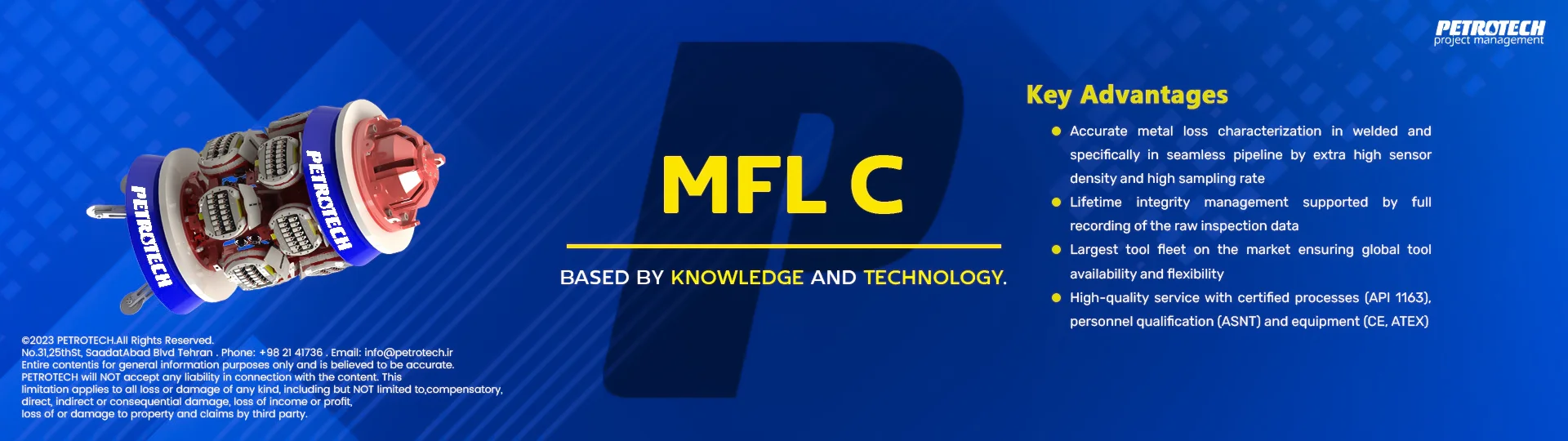

Longitudinal weld anomalies and narrow axial internal and external corrosion can pose a severe integrity threat to Petrotech. Conventional MFL tools that apply the magnetic field in the axial direction do not provide reliable detection and sizing of such anomalies.

Petrotech Transverse Field Inspection technology is also magnetic flux leakage based. However, magnetizer sections installed in the inspection tool induce a flux field in the circumferential direction. The proven design and high magnetization of the MFL-C tools coupled with an extra-high circumferential resolution provide reliable detection and sizing of narrow longitudinally-oriented metal loss anomalies.

This magnetizer system design ensures detection and sizing of general type metal loss anomalies, the same as conventional MFL tools. However, it is also specially developed for the measurement of longitudinally oriented anomalies such as tunnel corrosion, longitudinal weld anomalies.

We run our Petrotech MFL-C tools as stand-alone tools. We can combine it with other inspection technologies, such as MFL, UT, geometry, and mapping.

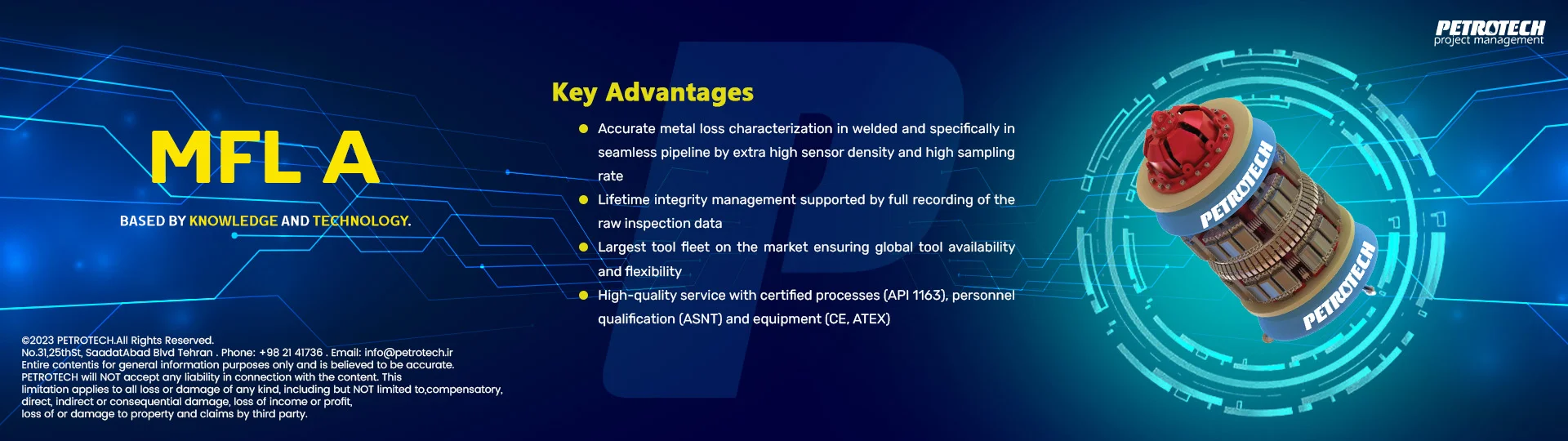

We use MFL for detection and sizing of general corrosion and other metal loss anomalies, especially circumferentially oriented. MFL tools have limited capability of detection and sizing of girth weld anomalies. Over the years several generations of the MFL systems have been subsequently developed involving significant improvement of their performance specifications.

Pipelines must be cleaned for several reasons: to maintain product transport efficiency, to ensure the purity of the product, and to successfully run In-Line Inspection tools.

Debris and sludge may seriously affect the process by reducing the effective pipeline cross-section. It can lead to a higher consumption of energy required to propel the same amount of product through the same line.

In case a pipeline is not regularly cleaned, the purity of the oil or gas is affected. It may consequently damage the downstream facilities and processes.

Petrotech develops specific cleaning programs adapted to particular lines based on the product and debris analysis, vast experience, and best industry practices.

The cleaning operations we perform are tailored to particular project conditions. Our equipment is designed and built to remove specific types of sludge, debris, and dust that can be found in a petrotech.

Petrotech offers pre-inspection and routine cleaning campaigns customized to the pipeline operator. We also clean water pipelines, mining pipelines, and pipelines with all standard products.

Wax Removal

We have vast experience in cleaning oil etrotech with high wax content using specially developed de-waxing pigs. These pigs are equipped with polyurethane blades, steel scrapers, and other arrangements ensuring effective cutting and removing wax sediments.

We use a range of cleaning pigs with supporting wheels to shift the load from the cups and discs to ensure that the cleaning effect is preserved for the whole run duration.

We use an efficient and economical system to separate dus

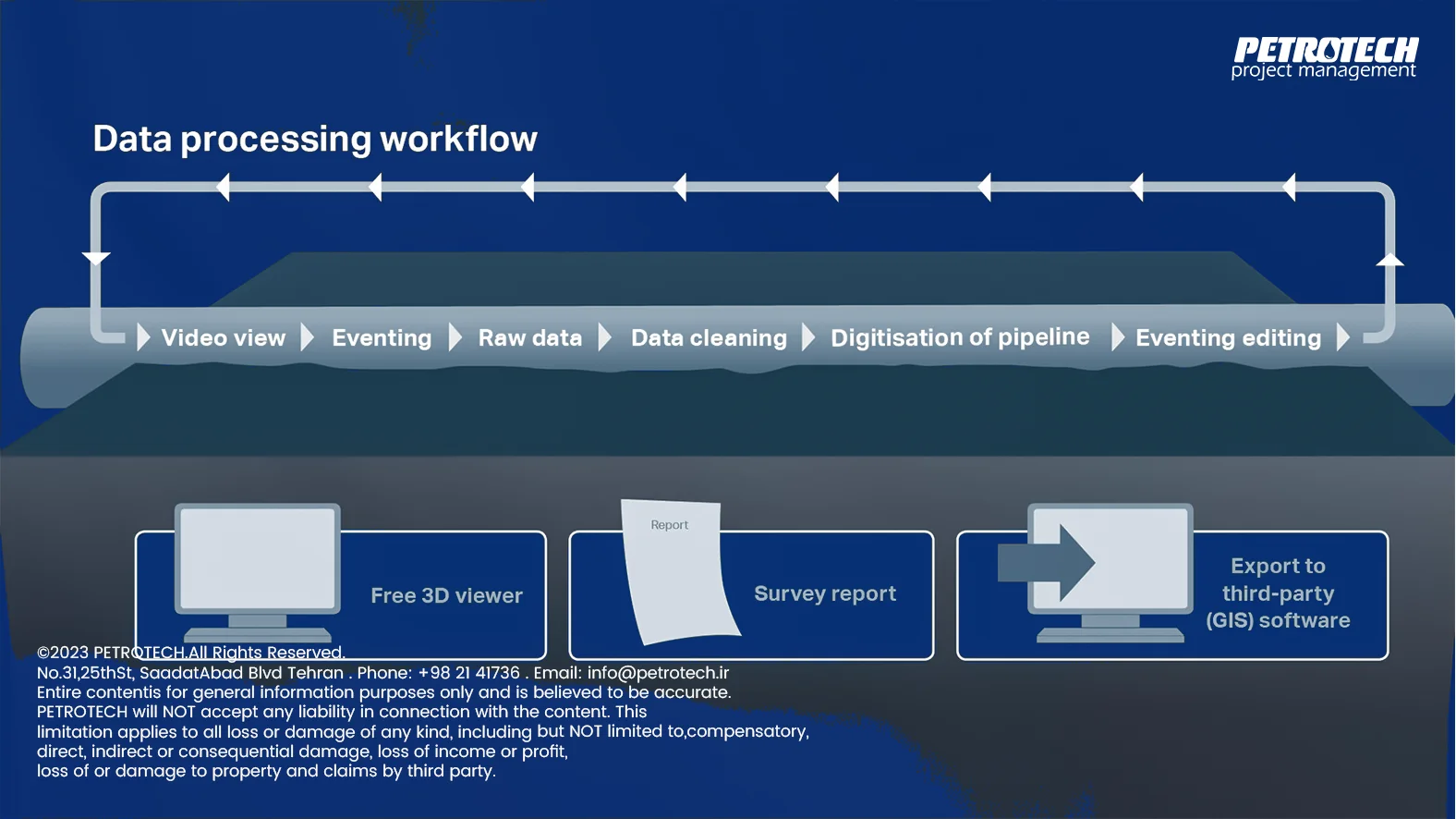

Very often, pipeline integrity-related data are dispersed. Many companies are challenged to manage an integrated approach due to multiple data storage locations used and massive amounts of digital information, making it difficult to achieve the integrity objective:

“Maintain the pipeline condition to operate safely, reliably, and economically within its design parameters.”

Integrating data related to the pipeline’s critical activities could result in a more effective integrity program. Petrotech software, with its built-in integration capabilities, achieves this objective and results in a more effective and efficient pipeline network integrity tool management:

It presents all available digital information on your pipeline network comprehensively.

It recommends maintenance optimization.

It visualizes the pipelines routing in 2D or 3D for quick and seamless assessments

Using Petrotech software, you can quickly and accurately integrate into your existing database by using various standards for assessments and you can extend your network life cycle efficiently.

our software In compliance with international standards, utilizes the results of In-line Inspection as a base to evaluate the pipeline integrity by:

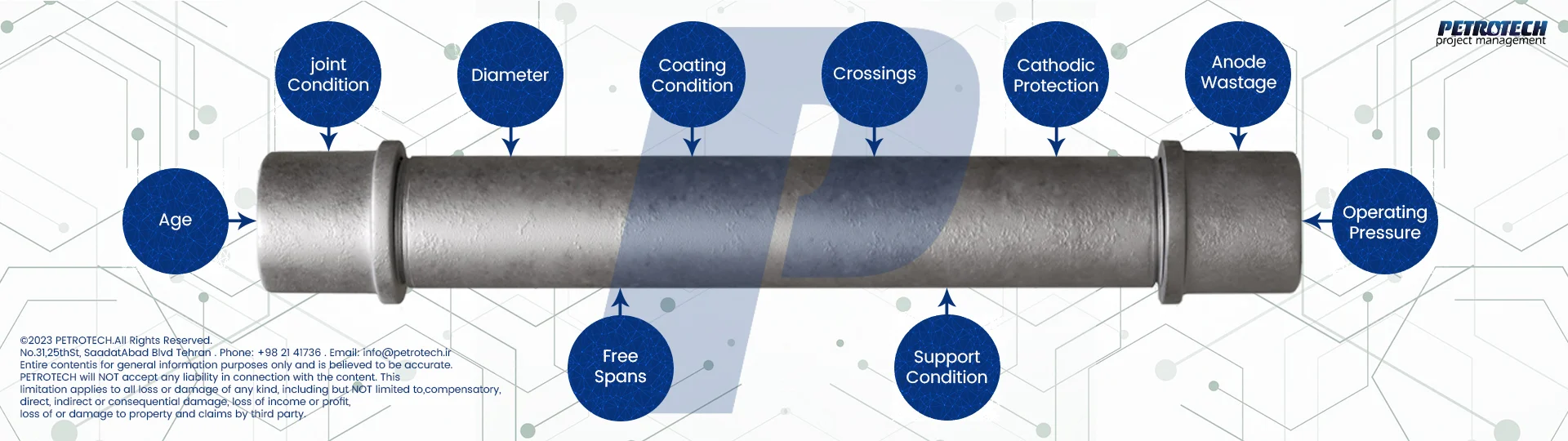

The term ‘unpiggable,’ while having no universally accepted definition, best describes pipelines that are difficult to inspect internally with conventional in-line tools such as smart pigs. There are a number of ways in which a pipeline is characterised as difficult to inspect. These are described below.

The size, or diameter, of the pipe can be restrictive to pigging tools, since most pigs are designed to travel through larger-diameter pipelines (12 inches and above). Some companies now offer pigs specifically for smaller diameters, and this has expanded the inspection options for pipeline operators.

Other physical characteristics that pose challenges to pigging:

Bends and connections can cause a pig to get “stuck”.Examples of problematic bends/connections include:

Recently, pigs have been developed with more agility to help them pilot their way through these configurations.

The flow within a pipeline affects pigging, as without sufficient product flow a pig is more likely to stall or become stuck. The internal cleanliness of the pipe can also cause problems with movement inside the pipe. Companies have developed processes to help with these issues, such as pigs that physically clean the pipe, or chemicals or gels that can be pumped through the pipe for the same purpose.

Below are examples of pipelines with flow or access restrictions:

There must also be sufficient access facilities at each end of a pipeline section in order to launch pigs into the line and retrieve them following a cleaning or inspection run.

Other restrictions on pipelines are related to how the pipeline was constructed, especially in older, longer pipes. There has been some research and development devoted to enabling pigs to travel longer distances and navigate through some of the restrictions listed below:

In-line inspection (ILI), such as pigging, is an important process to maintain the integrity of a pipeline. ILI tools are used to survey the pipeline and assess failure risks such as corrosion, blockages or leaks. These inspections can also help uncover important information about the pipeline and fill ‘gaps’ of knowledge.

The world of tubing inspection can be a complex field to delve into since they are classified as difficult to inspect lines, and especially if you do not know exactly what you are dealing with.

Finding the right team for the job can be a challenge to tackle, especially with all the “experts” out there and their custom-built tools that might not be as reliable or as effective or live up to certain standards.

In order to make an educated decision, estimate of equipment costs, estimate of labor costs, and a calculation of the time-frame necessary to achieve a task within, you need to have a certain level of knowledge in the field and industry to know what you are investing in.

In addition, that investment needs to make economic sense, both in terms of time and in terms of resources in order for it to be done effectively and not play a huge toll to the company’s budget.

Nondestructive testing is one of the most common methods to conduct tubing inspections and it cannot be executed easily, unless the crew involved knows exactly what they are doing with their gear, in terms of size, length, width, and technology, it could end in a disaster and deliver results that are not valid or precise to the point where, long term, it may cause a lot more damage and lead to a lot more costly resolution.

This task can be pursued in multiple ways, the most common being through the use of Ultrasonic or UT inspection technology.

Ultrasonic inspection relies on echo signals and waves to determine where the tubing is damaged and if it has any anomalies that need to be resolved quickly and compromise the overall build. Through these echo signals, the tool can indicate where exactly on the tubing are certain anomalies and through those calculations it can lead the workers to the right areas which need to be fixed in order for the tubing to function properly long-term and avoid potential severe damage that might occur if not done correctly or on time.

Petrotech offers specialised tubing inspection using 2″ Ultrasonic Wall Measurement (UTWM) tool, and through this tool, we can make a more sensitive and precise detection of flaws due to the nature of the technology that is implemented.

This tool allows us to analyse specific measurements based on effective resolutions and ensure sizing accuracy. It collects high-quality data in bidirectional motion and can collect thousands of reflected echo at one point. The 2″ UTWM also has the ability to improve analysis for pinhole with a diameter smaller than sensor aperture which also detects axial and circumferential location of anomalies.

Petrotech’s specialised tubing inspection method is multifunctional and allows us to inspect serpentine coils, boiler coil tubings in fired heaters, chemical power plants, downhole tubings in wells, and refineries.

The anomalies our UT tools can detect features such as:

This, in turn, leads to the detection of even the smallest flaws and anomalies within the piping or tubing system itself, nothing can escape this tool in terms of flaws and that is extremely convenient both for the workers and for the client as everything can be resolved effectively.

One huge advantage of selecting UT technology is the fact that it is shorter in length and it operates under lower pressure, but the most attractive feature by far is the fact that custom design arrangements can be made based on the tubing involved.

Having all of this information will, without a doubt, make you make a better investment when it comes to refinery tubing testing due to the fact that you now have a better understanding of how everything works, and know what tools you will need in order to properly test your tubes.

Petrotech provides information on pipeline conditions to clients and supports them in making maximum use of it to ensure the pipeline integrity is managed effectively.

Petrotech integrity is an essential aspect of asset management, and we recognize it through the provision of the following services to pipeline owners and operators:

Fitness-For-Purpose assessment reports include the assessment of the available pipeline data as subject to Level II assessment using specialized software tools to determine the remaining life as well as cost-effective and safe operating scenarios. The report also includes the corrosion growth rate of critical anomalies and the susceptibility of anomalies to cluster formation. We perform the assessment based on API 579 requirements.

INTEGRITY REPAIR AND MAINTENANCE OF OIL AND GAS PIPELINES

Petrotech Group provides integrity maintenance of oil and gas pipelines, a full range of pipeline repair, and modification services for offshore or onshore pipelines.

Our services respond to every world standards and client’s needs. We can do fast-responding repair and maintenance services for every health and environmental requirement.

Repair and maintenance services can be a wise approach in case of pipeline emergencies. By using our services, we can prolong the pipeline’s lifetime and significantly reduce repair time without the stoppage of pipeline operations. It is inevitably significant for the client’s convenience to increase pipeline functionality, taking into account the growth of the oil and gas pipeline grid.

We have developed expertise in pipeline repair using carbon fiber technology. It has the resources to carry out the field repairs and reinforce pipe wall strength. This technique ensures keeping MAOP as designed even if the actual pipe wall metal loss reaches 80% of the wall thickness.

Before field application, we carry out the necessary calculations and computer simulations using sophisticated software tools to ensure the reliability of the repair.

Our pipeline repair activities aim at minimum shut down requirements as well as minimum surface preparation for cost-effectiveness. We can provide certification and training of application technicians upon client request.

We present short and long term repair strategies to maintain and improve the lifetime of the pipeline economically. We assess the inspection data to identify permanent and temporary repair areas in compliance with the most stringent standards and recommended practices.

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.