Petrotech Company has been able to provide all engineering services for projects in the oil, gas and petrochemical industries, including well-known and reputable companies and manufacturers, experienced experts and efficient personnel, up-to-date equipment and valid standards in the field of electricity and precision instruments. Provide supply, installation, testing and commissioning from original design or renovation and revision.

Providing business services Business knowledge and experience of years of close and direct cooperation with reputable international companies and having an office located in the economic heart of Europe, Germany, Petrotech company is able to supply all equipment in foreign exchange, opening documentary credit, Delivery in foreign countries, domestic customs or at the customer’s site. Due to the implementation of some large projects by a team consisting of Iranian and foreign contractors, Petrotech has established a bridge between international suppliers, domestic and foreign contractors and end users, which brings relatively good benefits, including:

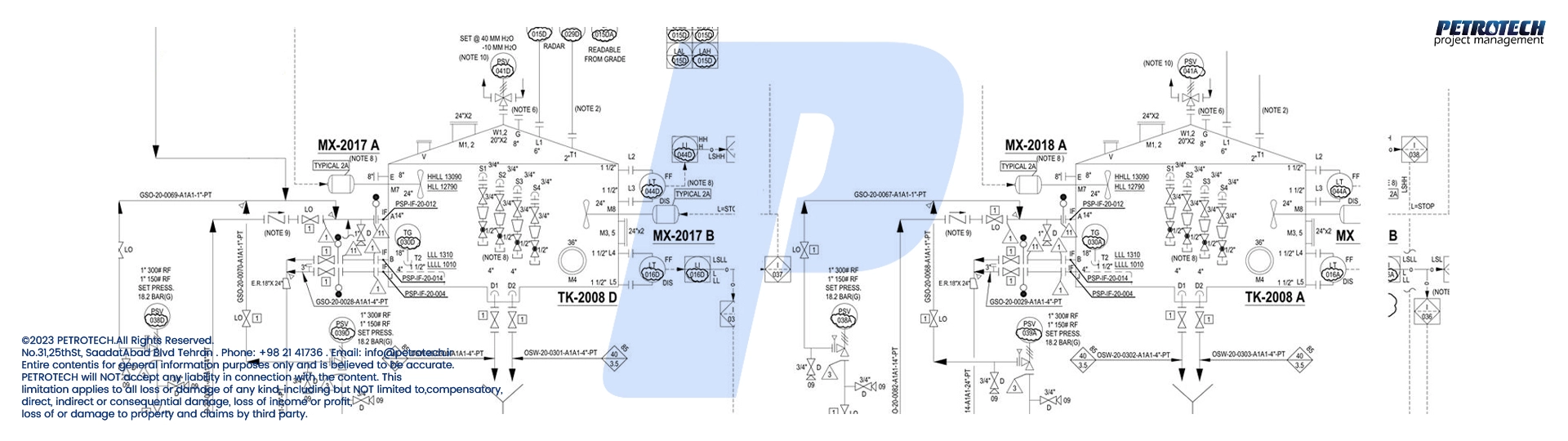

The most significant activities of the project department include consulting, design, documentation, equipment supply, construction of FAT, SAT control panels, installation and maintenance, and technical support. Also do other things like:

The purchasing team of Petrotech Company, using the capabilities of a team trained by large and well-known international companies, understanding the process of various industries such as oil, gas, petrochemical, etc., and relying on technical knowledge and using reliable communication channels with The help of specialized software and hardware to be on the path of an informed and satisfactory purchase is able to provide the services required by various industries.

This feature includes all the specifications related to the performance required of instrumentation systems in a particular process such as accuracy, sharpness, breadth, sensitivity, repeatability, dynamic performance and so on.

This is necessary to determine the protection required to ensure the proper operation of the instrumentation in accordance with safety requirements and operating conditions.

The degree of process turbulence during the measurement process must be taken into account. For example, significant pressure loss can be managed by some flow measurement techniques.

Durability and roughness should be considered according to the needs of the program.

The need for maintenance and ease of use, as well as its performance and impact on the current costs of systems and instrumentation equipment are measured.

The initial cost should be considered according to the needs and conditions of the end user.

The technical steps of installing the equipment and executing the electrical installations and instruments are done according to the schedule and codified. The technical engineering team and the executive team of Petrotech Company, located in the operational area, perform the steps of execution, installation and commissioning of the equipment in accordance with the pre-determined instructions and according to the designed engineering documents.

Performing electrical and mechanical performance tests, pre-commissioning and commissioning of all electrical parts and project control and automation, including panels, power transformers, motors, generators, DCS, SCADA, PMS, F&G and ESD control systems and loop Connections and connection testing of boards and equipment, calibration of equipment and other items are performed by the specialized personnel of the technical instrument engineering department of Petrotech Company. Testing and pre-commissioning operations after installation of equipment and units (Methodology & ICAPS)) is one of the effective factors to accelerate the project process and gradually and to ensure the readiness of the devices, performed by an independent group of installation Accepts. After completing the pre-commissioning work, the commissioning team together with the pre-commissioning team will start working in the Start up stage by studying the process documents and equipment commissioning instructions, respectively.

Installation is required to prove the performance of systems based on the purpose and specifications of the design, and all required tests and methods must be performed in accordance with the standards of each industry. This section has been established with the aim of providing installation, pre-commissioning and commissioning services of electrical equipment and precision instruments to various industries, and provides these services to new units and units in operation that need to be reconstructed or increase capacity. . The installation, testing and commissioning department of Petrotech Company, by using experienced and equipped teams, has the ability to install, pre-commission and launch operations in oil, gas, petrochemical, steel and cement industries, mining and … to do with the highest quality.

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.