Where pipeline operators do not have adequate records to substantiate and validate the material properties of their pipeline, they will need to undertake further material properties verification efforts to determine or verify key attributes, including, but not limited to, the following:

A framework for a holistic approach to material and property verification is the key to going beyond compliance.

Taking into consideration all required data to support threat management allows for asset safety and compliance, lifetime extension and asset performance maximization.

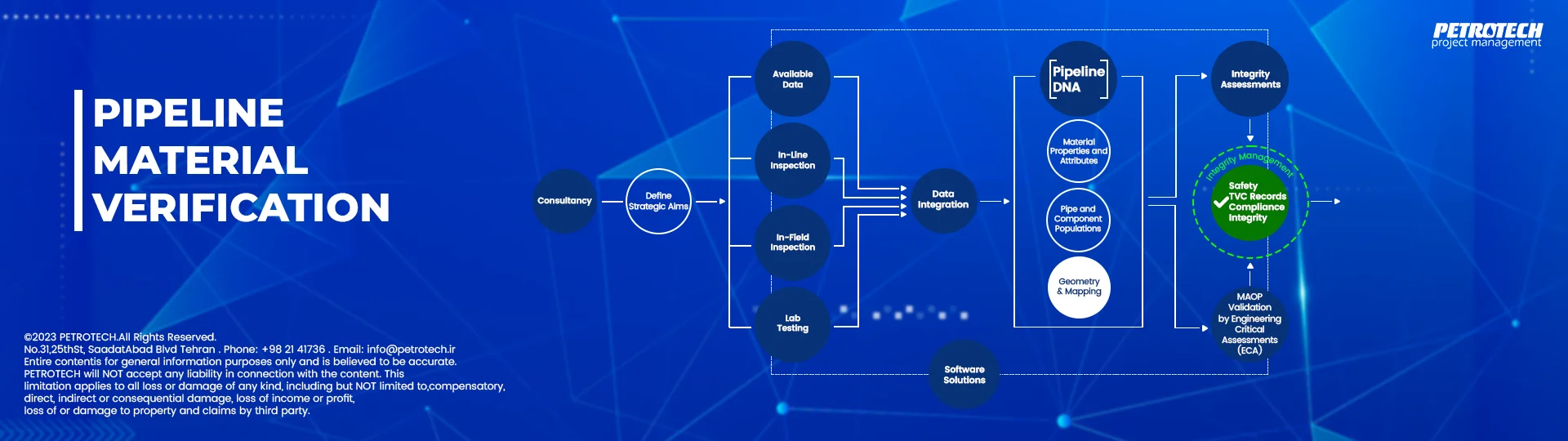

PETROTECH’s Materials Verification Framework offers a complete solution through every step of the comprehensive process, from defining the current status to achieving full compliance and beyond. Understanding that every pipeline is different, each element of the framework is applied as needed – creating a customizable solution.

Understanding integrity threats is key to establishing a strategy for the Materials Verification process. Threats can be identified based on existing inspection data or susceptibility analysis, and are aligned with the records’ status to determine critical gaps in material property information.

Selecting the appropriate in-line inspection (ILI) system constitutes a complete and traceable means to closing the gap in material property information and providing the right data for integrity engineering.

The Material Verification process is progressed through an optimized program of primarily non-destructive testing (NDT), performed in excavations. Testing is conducted with a specific scope and in locations that are available opportunistically or designed specifically to gather the data relevant to the requirement. Where needed, it makes sense to combine NDT with laboratory-based testing to support the verification of pipeline material properties.

PETROTECH assists in creating a comprehensive review and alignment of records, which is essential in breaking down the specific implications for your pipeline system into manageable processes based on an understanding of the quality of existing records in the context of integrity threats. PETROTECH assists by including, digitizing and assimilating information into a structured format to be integrated into the operator’s system of record.

Every Pipeline Materials Verification project is a consultancy project, unique in itself, and conducted and delivered as a complete service to ensure you really have the most accurate understanding of your pipeline.

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.